sales: gm@sspseals.com Toll Free: +1-888-238-SEAL Request A Quote

sales: gm@sspseals.com Toll Free: +1-888-238-SEAL Request A Quote

The pharmaceutical industry is one such quality conscious sectors that demand creative sealing solutions meeting cleanliness, traceability, and compliance to standards. Opting for the right industrial seals not only enhances the product quality or shelf life, but also avoids the formation of deposits that lead to cross-contamination. Made to satisfy all applicable hygienic requirements, pharmaceutical grade industrial seal component demonstrates high end mechanical performance and chemical resistance. This post discusses characteristics that you must look for when choosing industrial seals for the pharmaceutical sector.

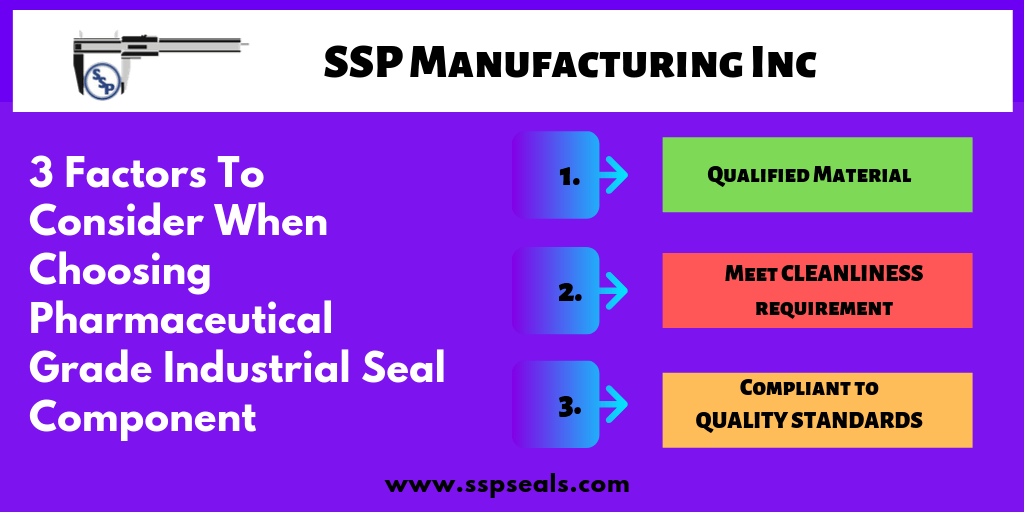

3 Things to Look upon When Choosing Pharmaceutical Grade Industrial Seal Component

As mentioned earlier, industrial seal quality affects pharmaceutical products’ purity and hence choosing the right seals are critical. In addition to meeting the technical requirements, industrial seals meant for the pharmaceutical industry must also:

The other points that must be evaluated include:

In order to guarantee maximum functionality of the pharmaceutical industry’s processing procedures and performance of equipment like vertical and horizontal agitator, mixers, centrifugal pumps, it is inevitable to invest on the right kind of industrial seal component. Getting this item from qualified and leading manufacturers also holds utmost importance as they take ultimately responsible for the quality of the products they offer. Additionally, leading manufacturers also bring you customized industrial seals considering the nature of applications, area of usage, and intended application period, among others. One such industrial seal manufacturer with whom you can undoubtedly start business is SSP Seals. The firm is known to offer premium quality FDA compliant seals that are specifically engineered to handle the specialized and hygiene requirements of the pharmaceutical industry.

Apr 17, 2024

Embracing Innovation in Sanitary Gaskets for 2024Mar 20, 2024

Explore All About Industrial Oil SealsJan 08, 2024

Top Reasons for Using Wiper Seal in Hydraulic SystemsDec 19, 2023

Typical Food-Grade Seal Failures and Strategies for ResolutionNov 22, 2023