sales: gm@sspseals.com Toll Free: +1-888-238-SEAL Request A Quote

sales: gm@sspseals.com Toll Free: +1-888-238-SEAL Request A Quote

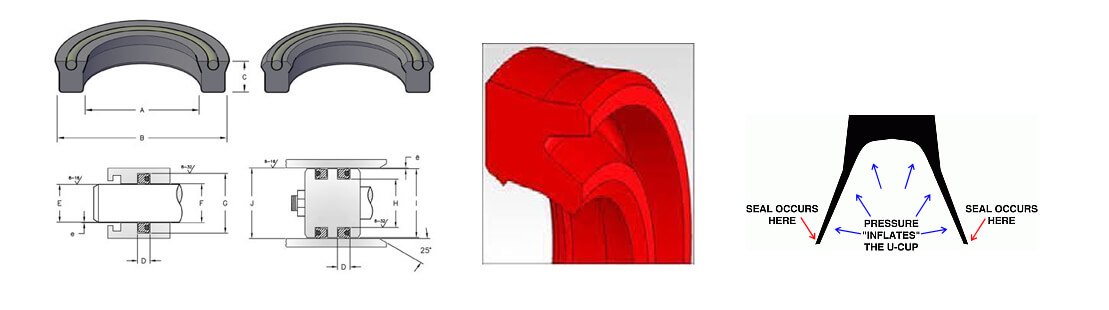

U cups are an integral part of a piston or cylinder sealing system. Although they may look round in shape, their unique U-shaped profile safeguards the pneumatic or hydraulic cylinder. There are two lips for sealing- inner and outer. The inner lip is movable or dynamic while the outer one is static. Within this, there are some sub-types of U-cups such as deep, standard, beveled, and so on. There are various types or patterns of U-cup seals, such as with or without an O-ring, and more. Usually made of polyurethane, these U-cups which resemble an O-ring are formed into U-shaped channels on either sides of the cylinder. This post discusses the types, design, and applications areas of U-cup seals.

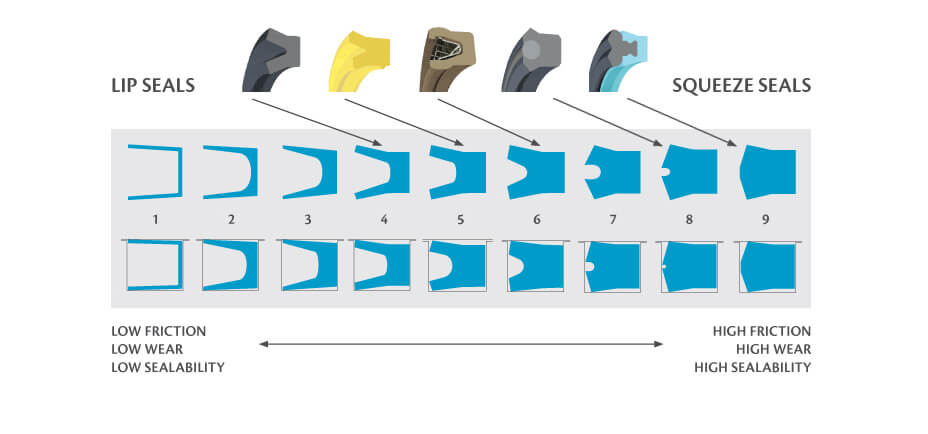

The U-cup was basically designed to seal low pressure rod or piston cylinders in only one direction. It is a loader which means it puts pressure on the lip seal so that it squeezes and offers the required sealing force. However, it can efficiently handle high and low pressure applications, vacuum, and extreme temperatures. The design depends upon the seal type whether it is static or dynamic. The other factors that are an integral part of the design are surface finish, whether O-ring loaded, Z-seal, inner and outer diameters, machining dimensions, tensile strength of the material used, and so on.

U-cups are used for piston and rod sealing and can be interchangeable in terms of applications. There are, as mentioned above, various types and sub-types of U-cups.

U-cup seals find applications in various industries, primarily in hydraulic and pneumatic applications. Here are some of them:

If you are looking for U-cup seals, ensure you meet all the compatibility requirements and also source them from reliable and certified manufacturers and suppliers. SSP Manufacturing Inc. has a market presence of close to three decades and are experts in making various types of seals and gaskets including u-cup sealing solutions.

Apr 17, 2024

Embracing Innovation in Sanitary Gaskets for 2024Mar 20, 2024

Explore All About Industrial Oil SealsJan 08, 2024

Top Reasons for Using Wiper Seal in Hydraulic SystemsDec 19, 2023

Typical Food-Grade Seal Failures and Strategies for ResolutionNov 22, 2023