sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

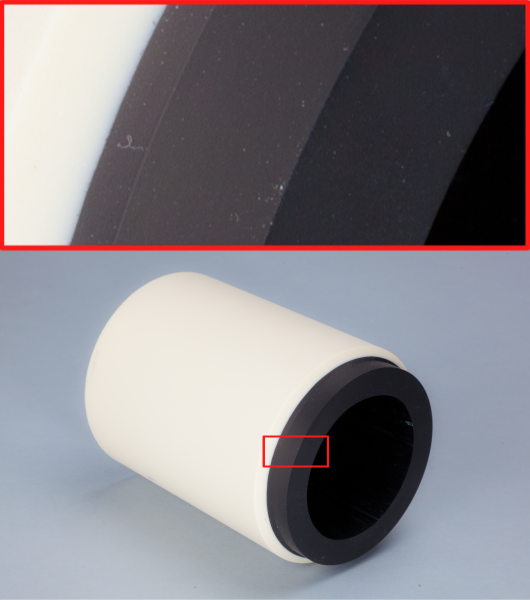

AFLAS ®, TFE/P refers to the range of copolymers comprising propylene and tetrafluoroethylene with a fluorine content of 54%. This copolymer is an ultra-high temperature compound that can withstand temperatures as high as 205 degrees Celsius. It can resist steam, petroleum compounds, and so on, which makes it a right choice for oil seals, O-rings, and gaskets to be used in critical applications demanding the highest degree of reliability.

Properties of AFLAS®, TFE/P Copolymers

The following properties of AFLAS® copolymers make a popular choice for various sealing applications.

AFLAS®, TFE/P Data Sheet |

||||||

| Properties | Condition | Standard | Unit | Unit | ||

|---|---|---|---|---|---|---|

| Color | Black | Black | ||||

| Hardness | 23°C/3 sec. | ISO 868 | Shore A | 83 ± 5 | Shore A | 83 ± 5 |

| Hardness | 23°C/15 sec. | ISO 868 | Shore A | 80 ± 5 | Shore A | 80 ± 5 |

| Modulus 100% | 23°C | DIN 53 504 | MPa | ≥ 7 | psi | ≥ 1015 |

| tensile strength | 23°C | DIN 53 504 | MPa | ≥ 9 | psi | ≥ 1305 |

| elongation at break | 23°C | DIN 53 504 | % | ≥ 110 | % | ≥ 110 |

| tear strength | 23°C | DIN ISO 34-1 | kN/m | ≥ 6 | lbf/inch | ≥ 35 |

| spec. gravity | 23°C | ISO 1183/td> | kg/m³ | 1730 | g/cm³ | 1,73 |

| rebound elasticity | 23°C | DIN 53 512 | % | 10 | % | 10 |

| abrasion | 23°C | DIN 53 516 | mm³ | 230 | mm³ | 230 |

| compression set | * | ISO 815 | % | 40 | % | 40 |

| compression set | ** | ISO 815 | % | % | ||

| compression set | *** | ISO 815 | % | 30 | % | 30 |

| minimum service temperatur | °C | -5 | °F | 23 | ||

| maximum service temperature | °C | 200 | °F | 392 | ||

| temp. max water/steam | °C | 170 | °F | 338 | ||

| temp. max hot air | °C | 230 | °F | 446 | ||

* 24h 70°C 25% def.

** 24h 100°C 25% def.

*** 24h 175°C 25% def.

Applications of Seals and Gaskets Made of AFLAS®, TFE/P

At SSP Seals, we regularly design and manufacture seals and gaskets for various applications across the following industries.

Feel free to contact our team to know and understand our capabilities in designing and manufacturing seals using AFLAS rubber sheet. Our experts would be happy to help you.