sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

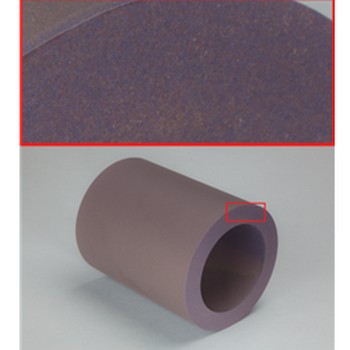

Overview of PTFE Bronze 40%

PTFE bronze 40% material is a type of Polytetrafluoroethylene. The PTFE itself stands for Polytetrafluoroethylene. However, the PTFE bronze 40% material slightly differs from the standard or virgin Polytetrafluoroethylene in composition. It consists of 40% bronze with 60% of virgin Polytetrafluoroethylene. PTFE bronze is used for the production of industrial sealing solutions due to its properties like high dimensional stability, comprehensive strength, hardness, etc. This engineered thermoplastic is chosen over virgin Polytetrafluoroethylene whenever durable application of industrial components like seals, gaskets, etc at high temperature is demanded. SSP Seals offers seals and gaskets made from PTFE bronze 40%.

Benefits of PTFE Bronze 40% Seals

We regularly produce bronze filled PTFE seals for our clients across industries. The following benefits of PTFE bronze 40% have made this thermoplastic highly popular.

PTFE Bronze 40% |

||||||

| Properties | Condition | Standard | Unit | Unit | ||

|---|---|---|---|---|---|---|

| Color | brown | brown | ||||

| density/specific gravity | 23°C | DIN 53479 | kg/m³ | 3110 | g/cm³ | 3,11 |

| Hardness | 23 °C/3 sec. | ISO 868 | Shore D | 60 ±3 | Shore D | 60 ±3 |

| Hardness | 23 °C/15 sec. | ISO 868 | Shore D | 59 ±3 | Shore D | 59 ±3 |

| ball indentation hardness | 23 °C | DIN 53456 H135/30 | MPa | 33 ±5 | psi | 4790 ±725 |

| tensile strength | 23 °C | ASTM D 4745-79 | MPa | ≥ 22 | psi | ≥ 3190 |

| elongation at break | 23 °C | ASTM D 4745-79 | % | ≥ 200 | % | ≥ 200 |

| compressive strength | 23 °C | DIN 53455 | MPa | ≥ 10 | psi | ≥ 1450 |

| thermal conductivity | DIN 52612 | J * 10³/ m * h * K | ≥ 4,0 | J * 10³/ m * h * K | ≥ 4,0 | |

| coefficient of thermal expansion | 25 °C - 200 °C | K-1 * 10-5 | ≥ 8 | K-1 * 10-5 | ≥ 8 | |

| coefficient of friction * | 23 °C | µ | ≥ 0,13 | µ | ≥ 0,13 | |

| minimum service temperature | °C | -200 | °F | -328 | ||

| maximum service temperature | °C | 260 | °F | 500 | ||

| young's modulus | 23 °C | DIN 53457 | MPa | ≥ 1375 | psi | ≥ 199500 |

* coefficient of friction dry dynamic Steel 16MnCr5 v=0,6m/s; p=0,05 MPa; t=5h

SSP Seals bronze filled PTFE 40% seals are ideal for applications in industries like automobile, mining, construction, etc. To know more about our products, please contact us today.