sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

The Food Safety Modernization Act has imposed stringent regulations on the way the food items are processed. The X-ray and metal detection systems installed in food processing lines enable food manufacturers to identify contaminants in food and ensure their quality. These systems, along with metal and X-ray detectable gaskets, and an efficient inspection program enable food manufacturers to reduce product recalls, customer complaints, and product downtimes. At SSP Seals, we support food manufacturers and other industrial clients with stringent sanitary requirements by providing metal and X-ray detectable gaskets in FDA-approved material configurations. These gaskets can be availed in different specifications to meet your application requirements.

At SSP Seals, we provide metal and X-ray detectable gaskets for use in sanitary pipeline systems. We help clients choose from the following types of gaskets:

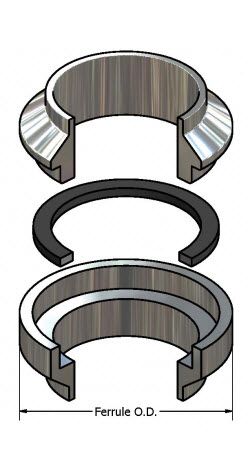

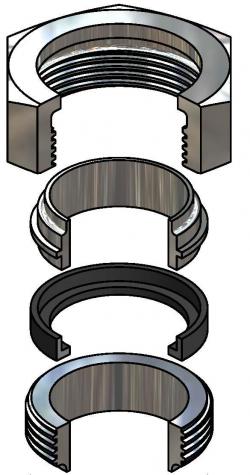

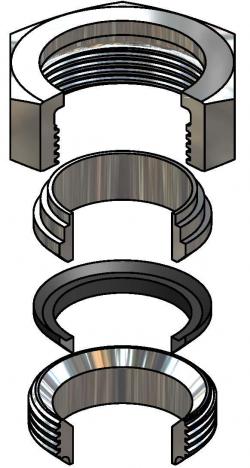

I-line Gaskets

John Perry Gaskets

Beveled Seat Gaskets

We can provide metal and X-ray detectable gaskets in the following materials:

We regularly design X-ray and metal detectable gaskets for use at the following:

Quality is an important requirement in all industries, where sanitation is prioritized. This can only be met using quality raw material and design. At SSP Seals, we assist clients in everything right from the design to the selection of the right material. Our experts work with them to understand their requirements before giving suggestions. For any queries regarding our X-ray and metal detectable gaskets, please contact us on our toll-free number 888-238-SEAL or mail us your requirements at gm@sspseals.com.

SSP Seals has emerged as one of the leading providers of FDA-approved sanitary gaskets, seals, and parts for food and beverage processing as well as pharmaceutical industries. We understand the sanitation and purity level requirements of these industries. In compliance with stringent regulations, all our metal and X-ray detectable gaskets are offered with a certificate of conformance. Our continuous technology investments have allowed us to stay true to our commitment of delivering quality products at cost-effective prices.

All our metal and X-ray detectable gaskets meet the most stringent standards for purity

*Buna does not pass U.S. Pharmacopeia Class VI Certification And Cytotoxicity and is not ADI Free®.