sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

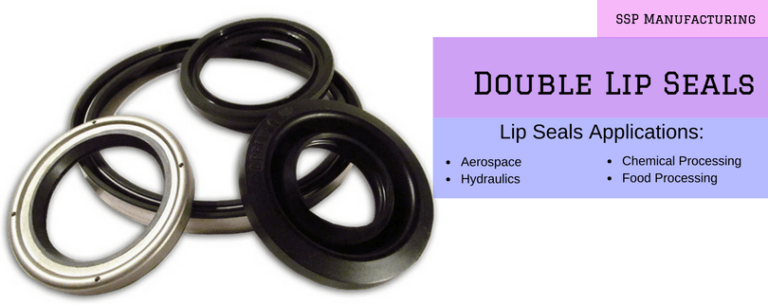

Lip seals – also known as rotary or radial shaft seals – offer several performance advantages, adding to their popularity in aerospace, climate control, electromechanical, fluid and gas handling hydraulics, pneumatic, and process control domains. Offered in various designs from single lip seal to multiple lip cartridge versions, these seals retain lubricants, remove contaminants, confine pressure and separate fluids. Being said about their popularity, are you intrigued to know how these seals are adding value to the various applications? If yes, this post discusses those applications in detail.

Where are They Used?

Rotary lip seals have several superior features. They possess excellent mechanical, and physical and low-friction properties. Owing to their outstanding resistance to wear, they can be used in demanding rotary situations and in a variety of applications ranging from slow-moving equipment to high-speed rotation.

The following list helps you understand the lip seal applications better.

1.Domain: Automotive

Applications: Front and rear crankshaft, accessory drive, blower and thermostat seals, Gear box assemblies, auxiliary power units and air turbine motor starters.

2.Domain: Hydraulics

Applications: Motors, pumps and hydrostatic transmissions

3.Domain: Food Processing

Applications: Mixers, kneading machines, separators, pipeline, conveying machines, cooling and wash systems.

4.Domain: Chemical Processing

Applications: Pumps, valves, separators, mixers, painting and coating equipment, combustion chamber, power turbine and compressor.

5.Domain: Aerospace

Applications: Actuators, door frames, engines, landing gear, flight controls, etc. Resistance to abrasive contaminants, minimum wear, and utmost performance at high temperatures are a few of the many advantageous offered by lip seals when used in the aforementioned applications.

Tips to Select Lip Seals for Various Applications

In order to get the sealing performance to the fullest, it is critical to choose the right lip seals made from the right material. For example,

Choose the right one after considering the operating temperature, lubricant in use and the application. In case, you are unable to make a choice, it is always better to approach an industry expert, who may a manufacturer of these seals. SSP Manufacturing, Inc. is one of the leading manufacturers of lip seals, which are used in various industries.

Choose the right one after considering the operating temperature, lubricant in use and the application. In case, you are unable to make a choice, it is always better to approach an industry expert, who may a manufacturer of these seals. SSP Manufacturing, Inc. is one of the leading manufacturers of lip seals, which are used in various industries.

Jul 22, 2025

Sustainability in Rubber Manufacturing: Is Nitrile Rubber Eco-Friendly?May 09, 2025

Innovative Sealing Solutions for High-Pressure Environments in Oil and Gas ApplicationsMar 28, 2025

PTFE vs. Rubber Seals: Key Differences and BenefitsFeb 26, 2025

How Seals and Gaskets Safeguard Food and Beverage Products?Feb 05, 2025