sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

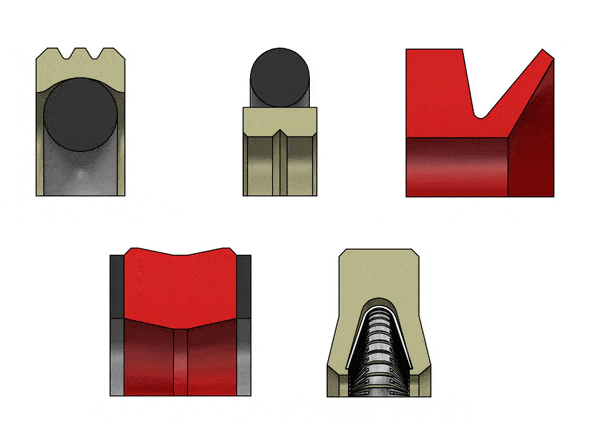

Also known as lip seals, these are ideal seals for rotating equipment. They seal these rotating parts such as rotating bores, strut seals, hydraulic pumps, and so on. A rotary seal comprises a sealing lip, a garter spring, and a metal case. The sturdiness of the metal offers rigidity and a firm fix to the connecting components. The lip seal is elastomeric performs the actual sealing function. The garter spring offers the required flexibility of movement and quite complements the lip seal. This is a basic design which can be customized to suit specific requirements. These seals are extremely versatile can be made of a variety of materials ranging from hard metals to plastic. The most common materials are steel, brass, silicone rubber, and EPDM. There are many processes or applications where a certain level of pressure and temperature needs to be maintained. In such cases, radial lip seals are used. Rotary seals for vacuum and pressure applications have a slightly different design which does not usually include a spring. Vacuum pumps are a major application area for these seals.

If you are an OEM who needs seals for oscillating parts or seals for rotating equipment, ensure you source them from reliable players who can cater well to your requirements. SSP Manufacturing Inc. offers a huge variety of seals and gaskets and has been there in the industry for close to 30 years.

Jul 22, 2025

Sustainability in Rubber Manufacturing: Is Nitrile Rubber Eco-Friendly?May 09, 2025

Innovative Sealing Solutions for High-Pressure Environments in Oil and Gas ApplicationsMar 28, 2025

PTFE vs. Rubber Seals: Key Differences and BenefitsFeb 26, 2025

How Seals and Gaskets Safeguard Food and Beverage Products?Feb 05, 2025