sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

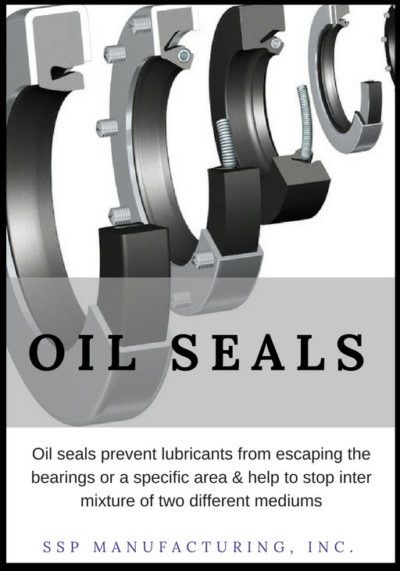

Oil seals are used in various industries for enhancing performance of moving parts. In the last post, we have discussed some general things about oil seals. In this post, we will discuss a few more crucial information related to oil seals.

Endless Options of Customization

Besides standard oil seals available, manufacturers offers the customization options as well. You can customize oil seals in any material (listed in the previous post), shapes, sizes, case design, spring position, spring tension, primary and secondary lip geometry, and so on. Also, oil seals can be customized to incorporate specific characteristics like:

Handling of Oil Seals

Oil seals must be handled and stored carefully to prevent oil leakage along with assuring expected performance when used in applications. The following rules must be strictly followed when storing, handling and transporting oil seals.

A Brief Discussion on Oil Seal Lubrication

When the oil seals are located near the lubricated bearings they get sufficient lubrication from the bearings. If these seals are used for sealing water, still they receive enough lubrication. In non-lubricating applications, additional efforts must be made to lubricate the seal. Dual seals are typically used for such applications, because they are pre-packed with grease between the sealing edges. While using dual seals, extra care must be taken during their mounting, in order to avoid the pressure build up due to the grease. Thus, lubrication is very important for oil seals, during the operation and in assembly, because it helps avoid friction losses, and ensures proper heat dissipation between greased edges.

Usually, these seals are supplied with an instruction manual, which has information on handling, installation, and troubleshooting tips among others. Hence, it is crucial for the user to read and understand the guidelines before using them in application.

With these basic understanding of oil seals, you would surely make a wise purchasing decision. It is always better to clear your doubts and queries from the manufacturer for making an informed purchase. SSP Manufacturing, Inc. is one of the leading manufacturers of oil seals in custom specifications.

May 09, 2025

Innovative Sealing Solutions for High-Pressure Environments in Oil and Gas ApplicationsMar 28, 2025

PTFE vs. Rubber Seals: Key Differences and BenefitsFeb 26, 2025

How Seals and Gaskets Safeguard Food and Beverage Products?Feb 05, 2025

Comprehensive Guide to FKM Fluorocarbon Rubber: Properties, Applications, and BenefitsDec 18, 2024