sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

Oil seals play a crucial role in all rotating and moving part assembly as they act as a physical barrier to retain lubricants, whilst excluding dirt, moisture and other contamination. They are manufactured in a wide range of sizes and specifications to meet several demanding sealing applications across industries. This post, which has two parts, discusses some of the must know things about oil seals. Read on to understand the seals better!

General Features of Oil Seals

Designed to offer optimum sealing performance, oil seals guarantee extreme durability even under high-peripheral speed. They are light-weight, compact, and exhibit high self-lubricating performance. As oil seals are manufactured using high-grade materials, they last long without showing the signs of any kind of hardening, softening or ageing.

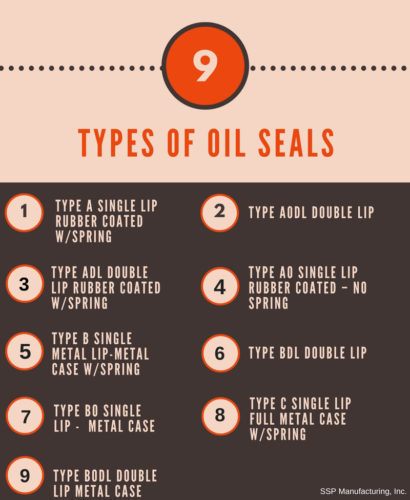

Types of Oil Seals

As mentioned earlier, oil seals are available in varied designs to best match the applications. A few of the commonly available types include:

Choosing the right seal is important as it determines the sealing performance by effectively preventing the leakage of lubricating oils and the ingress of contaminants.

Materials of Choice

Oil seals are made from several materials. However, the material must be chosen considering several parameters including operating temperature, environment, pressure, and maximum shaft surface speed, among others. The most commonly used materials for oil seal construction are as follow:

Applications of Oil Seals

Oils seals find immense applications in agriculture, automotive, construction, material handling, mining, oil and gas, and so on. They are used in the assembly of:

So far, we have discussed features, types, materials used in the construction, and applications of oil seals. In the next post, we will discuss few more general things about oil seals.

Jul 22, 2025

Sustainability in Rubber Manufacturing: Is Nitrile Rubber Eco-Friendly?May 09, 2025

Innovative Sealing Solutions for High-Pressure Environments in Oil and Gas ApplicationsMar 28, 2025

PTFE vs. Rubber Seals: Key Differences and BenefitsFeb 26, 2025

How Seals and Gaskets Safeguard Food and Beverage Products?Feb 05, 2025