sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

Seals refer to any adhesive device or material, which joins any two systems together and prevent leakage of fluid under the influence of pressure. These seals are developed using a different process, and are built in adherence with the industrial standards to provide effective performance in various power generation equipment, such as actuators, linear motion devices, gear boxes, etc. Their design, constructions and materials used vary according to the industrial usage. Read this post to get an insight on different types of industrial seals available, the materials used for their construction, and their significance.

Types of Industrial Seals Used in Power Generation Equipment

Power generation equipment deploys various types of industrial seals, such as bearing seals, grease seals, oil seals, rotary seals and many others. Some preferred industrial seals are explained below:

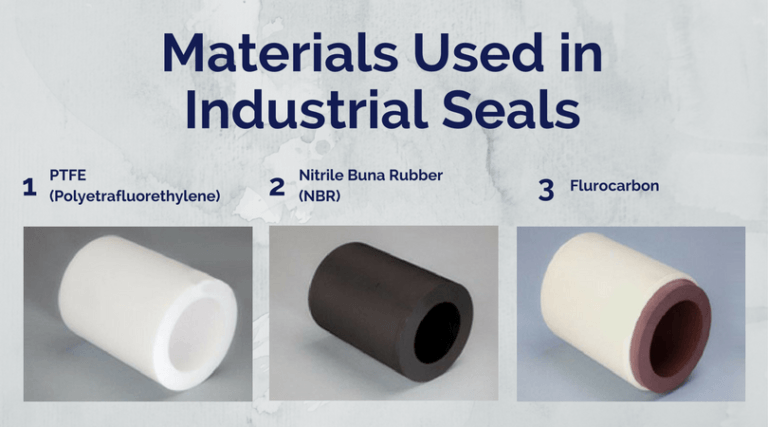

Materials Used in Industrial Seals for Power Generation Equipment

A diverse variety of materials are used in the fabrication of seals. Their specific properties like ability to withstand extreme temperature, corrosion resistance and many others, make them the most widely used material in power generation equipment.

Choosing the right kind of industrial seals can help you improve the quality, performance, and durability of the power generation equipment. If you are looking forward to buy any kind of industrial seal for your power generation equipment, you can bank on SSP Manufacturing, Inc. The company is one of the leading providers of standard and custom industrial seals in the USA.

Jul 22, 2025

Sustainability in Rubber Manufacturing: Is Nitrile Rubber Eco-Friendly?May 09, 2025

Innovative Sealing Solutions for High-Pressure Environments in Oil and Gas ApplicationsMar 28, 2025

PTFE vs. Rubber Seals: Key Differences and BenefitsFeb 26, 2025

How Seals and Gaskets Safeguard Food and Beverage Products?Feb 05, 2025